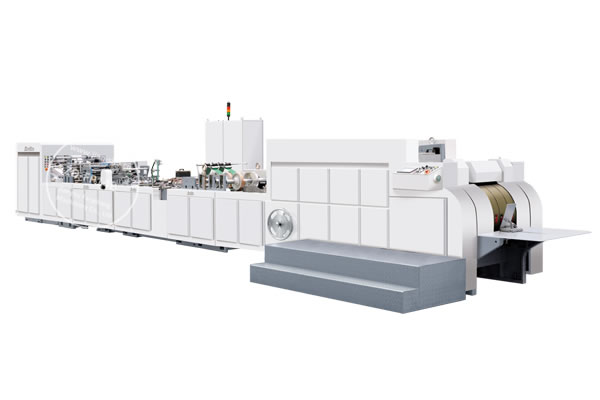

Model: ZD-FP08B/14/18/20

With over 2 decades of experience, customers often turn to Fangbang as their trusted Chinese tote bag manufacturing machine, as they know that we can guarantee them excellent services and advice on choosing the right paper bag making machine or tote bag production solutions to fit their needs.

Technical Specifications

| Model | |

|

| Paper Size Range | 350~730mm | 530~1050mm |

| Paper Tube (body panel) Length | 310~490mm | 360~630mm |

| Paper Thickness | 100~220g/m2 | 80~220g/m2 |

| Bag Body Width | 100~220mm | 180~350mm |

| Bag Body Length | 215~395mm | 250~480mm |

| Bag Bottom Size | 60~130mm | 70~160mm |

| Max. Production Speed | 80bags/min | 80bags/min |

| Total Power | 12kw | 13kw |

| Total Weight | Approx. 10000kg | Approx. 11000kg |

| Overall Dimension | L13500mm×W2400mm×H1600mm | L13000mm×W2400mm×H1700mm |

| Model | |

|

| Paper Size Range | 630~1250mm | 670~1340mm |

| Paper Tube (body panel) Length | 360~630mm | 360~630mm |

| Paper Thickness | 80~220g/m2 | 100~220g/m2 |

| Bag Body Width | 220~450mm | 240~500mm |

| Bag Body Length | 250~480mm | 250~480mm |

| Bag Bottom Size | 70~160mm | 80~160mm |

| Max. Production Speed | 80bags/min | 80bags/min |

| Total Power | 15kw | 15kw |

| Total Weight | Approx. 12000kg | Approx. 14000kg |

| Overall Dimension | L13000mm×W2500mm×H1700mm | L13500mm×W2500mm×H1700mm |

This page is dedicated to the Fangbang ZD-FP08B/14/18/20 sheet fed paper bag making machine, which has been specifically designed for those who run paper bag making factories. This paper bag making machine can produce paper bags in almost any size and out of almost any special paper quickly and efficiently. The resulting tote bag is widely used in commercial sectors ranging from groceries to pharmaceuticals and shoe stores.

Advanced pre-stack paper feeds one sheet at a time to each following process, with no need to stop the machine. This decreases downtime and increases customer profits. As a favorite among beginning paper bag companies, this equipment can carry out a series of tasks with one machine, including paper feeding, body panel creasing, glue application, body panel formation, and gluing the square bottom. As it is highly automated, labor costs are reduced, while still ensuring a consistent paper quality. The excellent gluing system applies a water based adhesive as well as a hot melt glue in a quick and neat process.

Sample

Here are a few paper bag samples made by our ZD-FP08B/14/18/20 paper bag machine. Remember that this machine can not make paper handles.

Features

Close-up Views